Factors That Make CNC Machining Superior to Stainless Steel Casting

The following are some beneficial factors of stainless steel CNC machining that make it a better replacement for stainless steel casting.

No Cost of Mold:

Unlike casting, CNC machining does require a mold. The CNC machines use various cutting tools that are directed via a numeric computer code to shape a product. Therefore, CNC machining saves the cost of the mold.

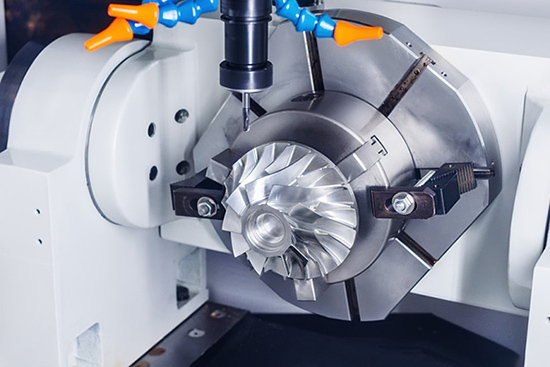

CNC machining can be used for a minute and complex part production. However, casting has a limitation that it is not suited for complex part production. Using casting for intricate products may give dimensional errors and a rough surface. However, CNC machining is performed over consistent feed, appropriate tooling, and low-tolerance dimensional coding, therefore the complex yet precise production can be efficiently performed using CNC machining for stainless steel products.

Faster Production Cycles:

Stainless steel CNC machining is a quicker manufacturing process compared to stainless steel casting. Mold setting is a time-consuming activity in casting followed by metal melting and cooling, and final product ejection from the mold. Against this, CNC machining includes generating a computer code, setting the workpiece, and post-production ejection of the stainless steel component.

+86-15220301231

+86-15220301231

+8615220301231

+8615220301231

jennyandcity

jennyandcity

E-mail

E-mail