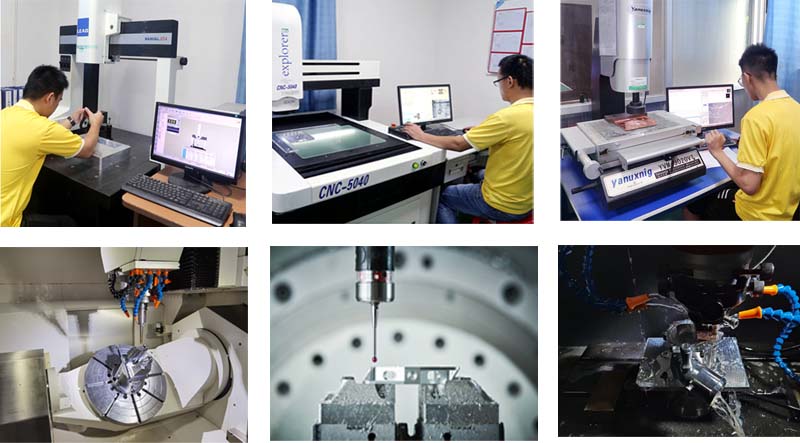

Selecting the suitable CNC machining partner for your business reduces a significant load and helps with efficient manufacturing in the long run. Dejin Precision was established with CNC machining services in 2002 and has become a parter of both domestic and import high precision CNC machined components. We possess some of the most powerful CNC equipment in the world and our 3 axis and 5 axis machines provide our customers with many material options.

First and foremost, your CNC service provider should have a thorough knowledge of different aspects of CNC machining.From product designing to prototyping and manufacturing, CNC service providers must have an understanding of everything.Not only that, they should know their way around a variety of CNC equipment so that they can recommend the perfect CNC machines according to your product and budget.

2. Experience in cnc machining services

Secondly, providers must also have good experience in different industries and the latest trends in manufacturing. This is important especially if your product is new so that the company can recommend the perfect manufacturing strategy.

However, remember that with a big company come big paychecks.

But what if the company is relatively new?

It’s simple. Check out their portfolio and see the work they’ve done in a short span of time. It will give you a clear idea of how well the company can work on short term and long term projects.

3. Precision and flexibility in cnc machining

Manufacturing with precision is the most important aspect of a product’s success.Make sure your CNC service provider takes care of every minute detail of the size, shape, dimension, and material used when manufacturing.And believe us, it has more to do with just designing products precisely.

It is also important to use raw materials efficiently with minimum wastage in order to reduce the excess cost to the company. Choose a CNC service provider who will efficiently manage the raw materials and product designing on their own.Secondly, an ideal CNC service provider must also work closely with you and quickly adapt the changes recommended by you.

4. Additional Services

Last but not least, if a CNC service provider has something extra to offer with their core services, you can save some extra money on those rather than going with different vendors for every service.

Some of the best CNC companies provide some additional services like custom machining, metal fabrication, reverse engineering, scale model prototyping, etc. These can help you find and solve some major manufacturing issue your product could be facing.Check out their website to find out what additional services they are offering. If their services match your requirements, you can mention those specifically when sending a quote to your service provider.

To wrap it all up, an ideal CNC machining services provider should save your time, money, and efforts apart from giving you a comprehensive and practical manufacturing solution.

Make sure you keep the above points in mind before selecting the perfect CNC service for your business.

We are a leading CNC machining service provider in China and will be more than happy to work closely with you as your strategic manufacturing partner. We understand the importance of one stop CNC machining services, so we has continued to grow and expand its product offering over the years and now we have the process of extrusion, stamping, CNC machining, soldering, cold plate, friction stir welding and assembly. We can provide low volume rapid prototype service as well as large production runs. Custom finish is also available, including anodizing, nickel plating, waxing, heat treating, annealing, stress relief, powder coating, tumbling, polishing and burnishing services. For some top-notch product manufacturing services, reach out to us now!

+86-15220301231

+86-15220301231

+8615220301231

+8615220301231

jennyandcity

jennyandcity

E-mail

E-mail