"CNC" is an English computer numerical control technology, referred to as CNC, CNC machining processing is a kind of engraving, and precision parts processing is a kind of accessories widely used in automobiles, communications, medical care, clocks, mobile phones, computers and other industries. Different from ordinary parts, precision parts are more precise and more suitable for some industries that require high precision. The machining of mechanical parts generally refers to the sum of the machining process of the parts and the assembly process of the machine. Other processes are called auxiliary processes, such as transportation, Storage, power supply, equipment maintenance, etc. Traditional machining is done by manual operation of ordinary machine tools. During the machining process, the machine tool is shaken by hand to cut the metal, and tools such as calipers are used to measure the accuracy of the product. Modern industry already operates with computer numerical control machines, which can be operated according to technicians. The programmed program directly and automatically handles any product and part.

It is a method of using digital information to control the movement and processing of machine tools, using numerical control technology to control the processing of machine tools, or a machine tool equipped with a numerical control system is called a numerically controlled (CNC) machine tool. Among them, the numerical control machine tool system includes: numerical control machine tool device, programmable controller, spindle drive device and feeding device. CNC machine tools are highly integrated products of mechanics, electricity, hydraulics, pneumatics, and optics. In order to control the machine tool, it is necessary to use geometric information to describe the relative motion between the tool and the workpiece CNC machining, and use process information to describe some process parameters that must be mastered in machine tool processing, such as feed speed, spindle speed, spindle forward and reverse rotation, replacement Knives, coolant switches, and other information are stored on information carriers (such as disks, hot stamping tapes, magnetic tapes, etc.) in the form of processing files (ie CNC processing programs) in a certain format, and then read by the CNC system. The machine tool, or input directly through the keyboard of the numerical control system, or through the way of communication input, makes the machine tool move and process the parts through decoding. Modern CNC machine tools are typical mechanical and electrical products, and are the technical basis for a new generation of production technology and computer-integrated manufacturing. Or directly input through the keyboard of the numerical control system, or through the way of communication input, through decoding, the machine tool can move and process the parts. Modern CNC machine tools are typical mechanical and electrical products, and are the technical basis for a new generation of production technology and computer-integrated manufacturing. Or directly input through the keyboard of the numerical control system, or through the way of communication input, through decoding, the machine tool can move and process the parts. Modern CNC machine tools are typical mechanical and electrical products, and are the technical basis for a new generation of production technology and computer-integrated manufacturing.

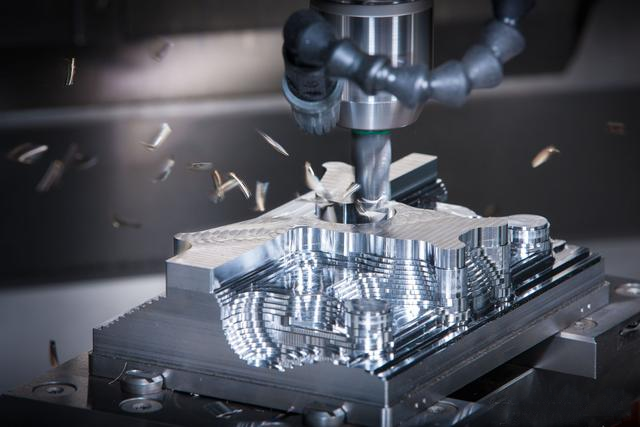

A CNC machining center is a CNC machine tool with a tool magazine that can automatically change tools and perform various machining operations on workpieces within a certain range.

Since the machining center can automatically complete a variety of processes in a centralized manner, human error is avoided, and the time for workpiece clamping, measurement and machine tool adjustment is greatly reduced for CNC machining, as well as the time for workpiece turnover, handling and storage. Greatly improve the processing efficiency and precision. economic benefits.

+86-15220301231

+86-15220301231

+8615220301231

+8615220301231

jennyandcity

jennyandcity

E-mail

E-mail