The power to avoid crashing with part holding the equipment by revolving the table or cutting tool gives room for a quick approach to part geometry is another contributing factor. Lastly, enhanced equipment life or longevity which is a result of revolving the table or cutting equipment to keep up with the best incisive position and consistent chip load.

5-axis machining is a mode of CNC machining. The machining centers we usually use are 3-axis machining centers. The 3-axis refers to the X-axis, Y-axis, and Z-axis of the machining center. 5-axis machining center is to add two rotary axes shafts to the three common linear axes of X, Y, and Z. These two axes are also called the fourth and fifth axes. Two of the three axes of A, B, and C has different motion modes in the vertical machine to meet the technical needs of various products.

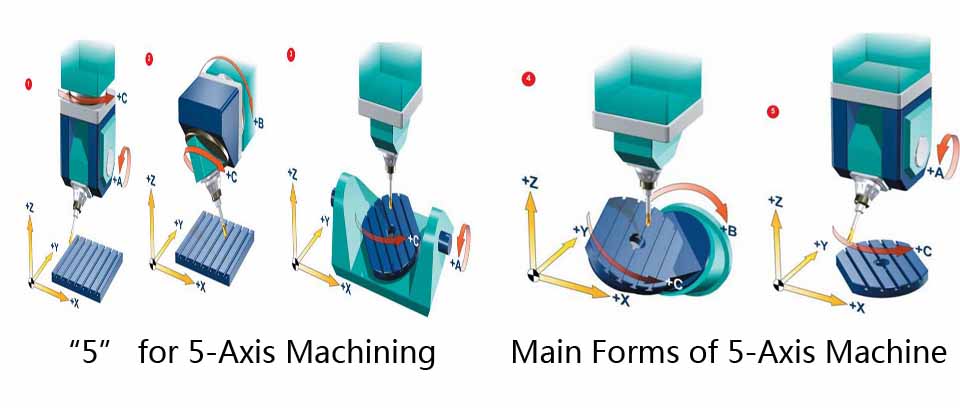

There are various types of 5-axis machines on the horizontal machining center, mainly including the following 5 forms: The 1st is a double swivel head form, two rotation coordinates control the direction of the cutter axis directly; the 2nd is droop swivel head form, two coordinate axes are at the top of the cutter, but the rotation axis is not perpendicular to the linear axis; The 3rd is double-swivel table form, the two rotation coordinates control the space rotation directly; the 4th is droop table, the two axes are on the table, but the axis of rotation is not perpendicular to the axis; the 5th is one swing one rotate from, two rotation coordinates one on the cutter and one on the workpieces.

Dejin was established with CNC machining service in 2002 and has become a supplier of both domestic and import high precision CNC machined components. We possess some of the most powerful CNC equipment in.

+86-15220301231

+86-15220301231

+8615220301231

+8615220301231

jennyandcity

jennyandcity

E-mail

E-mail